BioMass

Overview

The generation of photosynthetically produced biomass is the basis of all solar powered bio-fuels systems (bio-H2, bio-methane, bio-diesel and BTL. However, a common concern related to bio-fuels is that, as their production capacities grow, so they will increasingly competete for arable land required for food production. In contrast, the use of closed algal bioreactor systems has the advantage that they can be sited on non-arable land, eliminating competition with crop plants and opening up new economic opportunities for arid regions. In addition conventional crops used for bio-fuel production require substantial amounts of fresh water which is not the case for the biomass production of algae. Due to the increased photosynthetic efficiency of engineered algae and the use of closed bioreactors, considerable savings in net water use can be achieved, while increasing biomass yields over conventional crops.

Industrial Feasibility studies: To evaluate the potential economic viability of the algal biomass, Bio-H2, Bio-methane, and Bio-diesel processes under development, detailed feasibility studies including financial spreadsheets have been developed and are regularly updated. These studies evaluate the construction of a million-litre commercial facility and include consideration of capital, maintenance and labour costs, bio-fuel production levels as well as sales prices, the value of carbon credits and provides calculated values for Net Present Value (NPV) and Internal Rate of Return (IRR). All factors can be interactively adjusted to evaluate the effect on the IRR so the spreadsheet provides an extremely valuable tool for the evaluation of the viability of the process.

Antenna engineering: Photosynthesis is fundamental to all bio-fuel production. Green algae have evolved genetic strategies to assemble large light-harvesting antenna complexes (LHC) to maximise light capture for photosynthesis under low light conditions. The downside of this strategy is that under high light levels, of about 90% of the absorbed photons can be wasted as fluorescence and heat via natural photo-protective mechanisms [1]. These high levels of fluorescence result in major losses in process efficiency as most of the light is wasted at the surface of the bioreactor (Fig.1).

Fig.1: Flourescence losses: Algal culture illuminated with

blue light from below. The inset shows the red fluorescence

of excess light energy at the illuminated surface. Due to this

energy dissipation, which can be as high as 90% of the captured

energy, cells further from the illuminated surface receive

suboptimal light levels. Consequently the efficiency of the

overall bioreactor is reduced.

Recently we reported the first light-harvesting antenna mutant

which is being developed for improved biomass production efficiency

[2]. This mutant exhibited the following benefits for bio-fuel

production:

-

Reduced fluorescence and LHC dependent heat losses.

-

Increased photosynthetic efficiencies under high light conditions.

-

Improved light penetration properties.

-

Potentially reduced risk of oxidative photodamage of PSII.

Related mutants are also being developed for Bio-H2, Bio-methane, Bio-diesel production processes.

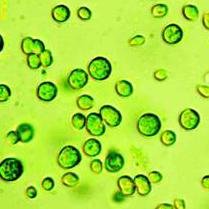

Salt tolerance: Salt-tolerant algae are being engineered (Fig.2) to optimise biomass, bio-H2, bio-methane, bio-diesel and BTL production systems and offer the following advantages:

-

Salt tolerance confers a selective advantage to the cultured algae and reduces contamination.

-

The use of salt tolerant algae minimises the need for fresh water (an increasingly precious resource) and allows much more abundant salt water sources to be used.

-

By using salt tolerant algae bio-fuel production can be coupled with desalination. Although this principle is true for all bio-fuel production processes it is particularly attractive for Bio-H2 producing systems. This is because the combustion of H2 and oxygen gas (released from sea water by algae via the process of photosynthesis), yields fresh water. To facilitate water capture, the H2 and oxygen must be converted to electricity using large scale stationary fuel cells connected to an electricity grid.

Fig.2: Engineering salt tolerance: Control

0%-50%: Wt algae cultured in 0%, 10%, 25% and 50% of the NaCl

levels find in sea water. DE 50%: Salt tolerant

algal cell culture growing in 50% NaCl levels found in sea water.

Bioreactor design and engineering: Closed bioreactor systems are more expensive than open pond systems. Our feasibility studies strongly indicate that in the long term these systems offer the most profitable route for bio-fuel production, if they can be reduced in cost. This is because they offer the advantage of reduced water use (~1000x less than required for conventional crops), increased production efficiency (currently 5-fold increase in biomass production rates over open pond systems) and reduced contamination. Currently kinetic parameters are being carefully evaluated to facilitate optimal bioreactor design for normal and reduced antenna mutants and to reduce cost to wards 10 €/m2.

References

Polle, J., S. Kanakagiri, and A. Melis, tla1, a DNA insertional transformant of the green alga Chlamydomonas reinhardtii with a truncated light-harvesting chlorophyll antenna size. PLANTA, 2003. 217(1): p. 49-59.

Mussgnug, J., et al., Engineering photosynthetic light capture: Impacts on improved solar energy to biomass conversion. Plant Biotechnology Journal, 2007. 5: p. 802-814.

Doebbe, A., et al., Functional integration of the HUP1 hexose symporter gene into the genome of C. reinhardtii: Impacts on biological H2 production. Journal of Biotechnology, 2007. 131: p. 27-33.