BioDiesel

Overview:

Bio-diesel is developing into one of the most important bio-fuels

of the future. This is because virtually all industrial vehicles

used for farming, transport and trade are diesel-based. Currently,

bio-diesel is produced from animal or plant oils in a reaction known

as transesterification. Oils are first extracted from

the plant and then reacted with methanol and a catalyst such as

sodium methoxide to produce bio-diesel and glycerol1.

Bio-diesel is considered to be an excellent renewable carbon-neutral

fuel, but to enhance its economic viability, improved production

systems must be developed.

In the past decade, the bio-diesel industry has seen massive growth both in Australia and globally. The increased demand for vegetable oils for the production of bio-diesel has lead to significant pressure on the domestic vegetable oil market. In response to this, a number of crops are now being grown solely for the purpose of bio-diesel production, most notably soy, canola, jatropha and palm oil. With more crops being dedicated to production of bio-fuels, increasing pressure is being put on the food supply. Eventually the combined pressure of food and fuel production is predicted to produce a phenomenon known as ‘peak soil’. With only 13.3% of the world’s land mass considered to be arable, and oil-producing crops being specific to certain climates, it is not possible for land-based plants to meet global fuel demand alone.

Algal production systems have long been recognised as the most efficient means of producing biomass for food or fuel; they do not require arable land and therefore don’t compete for space with existing crops. Over the same area micro algae can produce 20-300 times more bio-diesel than traditional crops (Table 1) and the remaining algal cake can still be useful for animal feed, fertiliser or other bio-fuel production systems. However, the initial set-up and maintenance of such systems has, to date, always proven to be cost prohibitive for fuel.

Plant Source |

Bio-diesel (L/Hect/Year) |

Area required to match current global oil demand

(million hectares) |

Area required as a percentage of global land

mass |

Soybean |

446 |

10932 |

72.9 |

Rapeseed |

119 |

4097 |

27.3 |

Mustard |

1300 |

3750 |

25.0 |

Jatropha |

1892 |

2577 |

17.2 |

Palm Oil |

5950 |

819 |

5.5 |

Algae (low) |

45000 |

108 |

0.7 |

Algae (high) |

137000 |

36 |

0.2 |

Table 1: Comparison between crop efficiencies for bio-diesel production 2,3

Common stream:

The first stage of all bio-fuel production is the production of biomass. Following the modules set out for improving photosynthetic efficiency, we will be utilising methods developed in the bio-hydrogen project to modify algal species best suited for bio-diesel production.

Specific stream:

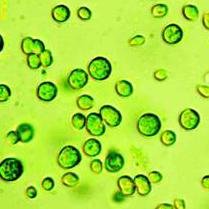

The Solar Bio-fuels Consortium is building up a large collection

of local algal species from marine, brackish and fresh water environments.

Each of the isolated species is being grown under a variety of

conditions and then screened for properties desirable for bio-fuel

production. Using scaled-up systems, the most promising local

strains are being compared to the highest oil-producing algal

species for bio-fuel production from around the world. The key

properties being screened include:

- Efficiency of oil production

- Engineering-improved light capture efficiency

- Engineering-improved salt tolerance

- Growth rates

- Resistance to fluctuating climatic conditions

- Competitiveness in mixed culture

- Valuable by-products (eg. protein and carbohydrate composition, as the processed algal cake can be further utilised for animal feed, fertiliser or in other bio-fuel production systems

- Bio-reactor design

References:

Fukuda, H., Kondo, A. & Noda, H. (2001) Biodiesel fuel production by transesterification of oils. J Biosci Bioeng 92: 405–16.

Sheehan, J., Dunahay, T., Benemann, J. & Roessler, P. (1998) A look back at the U.S. Department of Energy's Aquatic Species Program—biodiesel from algae. National Renewable Energy Laboratory, Golden, CO; Report NREL/TP-580–24190.

Chisti Y. (2007) Biodiesel from microalgae. Biotechnol Adv 25: 294–306.